Concrete is an excellent building material. In consists of a binder (clay, lime or Portland cement), aggregate (sand and gravel) and reinforcement (rebar, wire or fibers). It is a relatively low-tech material and can be made very durable and strong, even by the beginner. Concrete has several methods of implementation, depending on what you are using it for, and in many countries, entire buildings, from the floors to the roofs, are made out of concrete, and will last for centuries.

Concrete is considered a “plastic” material in that initially it is a liquid that sets into a hard shape. To say that it dries is not entirely accurate, because actually, a chemical reaction takes place when concrete sets. The binder reacts with water and air to produce a rock-like substance. This reaction is not reversible if you use Portland cement as a binder. Other forms of concrete, like Roman concrete, use a mixture of silica, lime and clay to create a binder that reacts at room temperature, instead of the 3000 or so degrees needed for Portland’s initial reaction. Roman concrete has the added advantage of turning into limestone over the years, increasing its durability. Some folks have even suggested that the pyramids in Egypt may have been constructed in this way. Those stones may have initially been made from a primitive concrete, which slowly turned to stone over a thousand years.

When working with concrete there are a couple of general things to remember:

Concrete is a strong and diverse building material. It can be used in so many ways, including slabs, poured, formed with fabrics, ferrocement, laminated ferrocement, and mixed with acrylic for super thin and lightweight applications.

Pouring concrete into a form is perhaps the most common way to use concrete. The size and shape of the form is determined by the project at hand.

Pouring concrete is relatively cheap and very fast. The speed with which you put up a building depends largely on your crew and tools. But even with minimal of both, the pour will go faster than you think; it is the setting up of forms that often consumes more time.

The key to pouring concrete is the form. The nice thing about forms is that you can design complex shapes and styles into the construction without having to carve hard to work materials like stone and concrete.

Form systems are usually made out of easy to mold materials, like fiberglass, plastics, metal or wood. To make a mold using these materials means that the detailed work can be done in a soft, workable medium. You can work out the kinks and features without having to rebuild the building.

Concrete forms need to be strong and need to be able to hold that strength for at least a few days. Wood is a good material, but metal is better. Flexible forms have some advantages, especially for round and artistic structures.

Recently, many forms have been made with inflatable plastics. These forms are easy to transport, setup, and modify. They are rather fragile, however, and if the form deflates prematurely, you risk loosing the structure. Their advantages are impressive, and some of the largest concrete buildings have been built with this method. Imagine inflating a form, spraying it with concrete and reinforcement, and letting it dry for a few days. Yes, that’s right, a finished building in a few days. No other forming system can be set up so quickly.

You can make concrete forms for foundations, floors, walls, roofs, window and door frames, benches, and more. In other words, you can pour your whole building, step by step.

Design and set up your form (making sure it is well braced to withstand the weight of the concrete), add metal reinforcement and then pour your mixed concrete into it. You can add rocks or other large objects to reduce the amount of concrete needed. Make sure that you tamp your concrete as you pour it, so that no bubbles remain. It is best to mix the concrete as dry as you can, as it will be stronger that way. Adding fibers to the mix also increases the strength.

Leave the forms on for a day, or until the concrete is hard to the touch. Cover your concrete to prevent rapid drying, and apply water as necessary to guarantee a slow cure.

We have a how-to on how to pour a fabric-formed foundation, if you are interested.

Latex concrete offers a strong, fluid end product. It involves the application of a watery cement and acrylic mix to a fabric that is stretched out between main structural supports.

Latex concrete is fast, easy and lends itself to fluid, draping shapes. Its advantages are:

As you apply each layer of latex concrete, the fabric will get harder and harder. It dries fast, so you can apply each coat in fairly quick succession.

We made a roof out of this method and were very impressed. For more detailed instructions, see our guide on making a latex concrete roof.

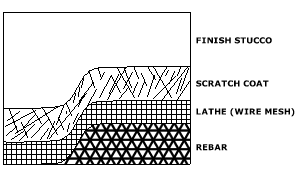

Ferro-cement is concrete that is heavily reinforced with both wire mesh and rebar. This type of construction is extremely flexible, which seems strange for something as hard and dense as concrete. Because of the reinforcement, ferro-cement does not need to be as thick as concrete, and designers consider it more as a tensile skin that can be made in just about any shape.

Ferro-cement is concrete that is heavily reinforced with both wire mesh and rebar. This type of construction is extremely flexible, which seems strange for something as hard and dense as concrete. Because of the reinforcement, ferro-cement does not need to be as thick as concrete, and designers consider it more as a tensile skin that can be made in just about any shape.

It is more expensive than poured concrete, but also more versatile, allowing you to be far less rigid with the shape of your construction. It is very durable and strong, but requires a bit of skill to get it right.

The process is to create an armature out of rebar, then cover it with lathing and wire mesh, and stucco thin layers of a sand/cement mix. Additives are used to give the concrete different added benefits, like quick or slow curing times, added strength or water proofing. As far as concrete is concerned, ferro-cement is one of the most versatile methods available.

It takes a little practice, but once you get going, it is surprising how fast you can get a large area done. Be aware that the hardest stucco to do is overhead (like the underside of a ceiling). If you can avoid this in your design, it will save you a lot of shoulder and neck ache. Once you’re a little more experienced, it won’t be so bad, and adding acrylic to your mix makes it much easier (as it is stickier).

Ferro-cement is a form of building that lets your imagination run wild. For more information, take a look at this how-to.

Laminated Ferro-cement, or LFC, is a way of making strong, thin panels that can then be used in building.

LFC has a lot of potential in the building arena. It consists of making a simple form on the ground, placing reinforcement, pouring concrete, vibrating it, letting it dry and then using it in your building.

The procedure goes like this:

While it maintains the strong and thin nature of ferro-cement, it has some added advantages.

The trick to LFC is making the forms. You will want to include into the design a way to attach each panel to the next. You also want to make panels that are not too heavy to move. You can make panels for roofing tiles, wall sections, even flooring.

We have done tests on this system, making two fairly small, flat panels. One used one layer of lathing, the other used two. We were extremely impressed at the strength of the panels. The first bent and cracked under the weight of a grown man (mostly because he started to bounce a little!), the second did not. It is a technique we would like to use properly one day.

The possibilities of this technique are limitless, and whole ships have been made with this process.

Surface bonding consists of dry stacking a brick wall, and then covering it with a special fiber-reinforced tensile stucco.

Surface bonding is a method of construction using bricks. The bricks can be made out of concrete, adobe, CEBs, EPS-crete or any other strong brick material. Bricks should be consistent (in shape and size), with variances less than 1/8”. Surface bonding is strong, simple and fast, and is suited to the home-builder. Careful attention to a few details in the planning stages can avoid hassle down the line and make for a fast and easy construction process.

These walls are stronger than normal, mortared brick walls, and construction and labor costs can be cut in half. If the bricks are properly sized to the room dimensions, cutting bricks can be mostly avoided, and construction speed will improve. It is not uncommon to dry stack an entire home in one or two days.

Once your walls are dry stacked, you will cover them with a stucco of cement, lime, acrylic, and fibers. No sand is needed. Two layers is sufficient, and you should wet the bricks beforehand to avoid rapid drying of the stucco.

Surface Bonding is not complicated, but the steps and construction must be done right to enjoy the benefits of this method. Most of the preparation beforehand will save a lot of time and money during the actual construction of the building.

The most important factor in constructing a surface-bonded wall is to have quality bricks. Low-quality bricks don’t stack well, and may shift. If you can find a brick supplier that can produce smooth, low-variance bricks, you will save tons of time.

Percrete and EPS crete are a lightweight concrete that can be poured into forms. They also have added insulation.

These are very similar in that they use a lightweight aggregate instead of sand or gravel. The aggregate is either perlite, an expanded volcanic clay, or shredded Styrofoam. These materials give the resulting concrete added insulation value and a greatly reduced weight. They are not as strong as regular concrete with sand, but they can be made strong enough for any home application. They are most often used as a filling between two concrete walls to increase the insulation value of the wall without a decrease in strength.

An advantage of using Styrofoam is that is a good use of an otherwise non-recyclable material. Styrofoam can be found for free or cheap in the form of disposable plates and cups, packing materials, old insulation, and many other forms. You want the aggregate to be in small pieces, 1/2″ or less, so shredding is necessary.

We have not used this style of concrete. However, we have used something similar, making a wall with Styrofoam in the center, to which we attached lathing on each side and applied a coat of stucco. This made a quick, insulated wall, and the stucco was easier than with a ferrocement wall, because it had a backing.