Converting electricity into heat is one of the most expensive uses of energy. If you’re not convinced, look at the power usage of electric appliances like microwaves, space heaters, water heaters, ovens, or coffee pots. The difference can be seen between your electric bill from a cold month, when you have to continually run your central heating, and during summer months, when the ambient temperature does not need to be heated.

If you live off-grid, you tend to be far more aware of what it takes to create electricity; you can literally watch your batteries’ voltage drop lower and lower when using an inefficient appliance. However, if you are tied into the grid, you should almost be extra vigilant as regards your power usage. Not only do you have to pay for it each month, but also the power plants that produce your electricity are rarely sustainable or environmentally conscious.

When considering the issue of heat, there are several green options, the best of which is the sun. Solar thermal energy can be harnessed in many ways to heat your water, food, or home. For the purpose of this article, we will be concentrating on an active thermal space heater to heat a room or house. The unit takes one person two days to construct, one day to install, and costs under $100. The temperature inside the unit easily reaches 160 degrees Fahrenheit on a 50-degree day, and can be blown into the house using a fan that pulls less electricity than a light bulb.

Please note that the unit should be installed on a south facing wall (if that is not possible, then a west facing wall will at least give you heat in the afternoon).

One 8’x4’ sheet of ½” foam insulation, with foil backing

One 8’x4’ sheet of transparent, corrugated plastic

Three 10’ pieces of 4” metal channel

Two pieces of 24” x 13.5” sheet metal (for shorter room-see step 1)

Four 8’ pieces of molding (1”x1/2 “) 16’x4’ of black screen (metal or plastic)

One 8’ length of 4” dryer vent tubing (for shorter room-see step 1)

Two 4” hose clamps 4” 100CFM fan (if fan is 12 VDC, you will also need a converter from an old computer or printer)

Screened vent Snap switch (45C action, 30C reset, Normal Open, Thermostat Temperature Control Switch, we use model KSD301)

10’ of 12 gauge stranded wire

Cheap extension cord (to reach your nearest plug)

½” metal screws

1” wood screws

12 x 2” screws and concrete anchors

Staples

Silicon

Black paint

60” of 1” wide metal, 1/8” or ¼” thick

Insulation for the dryer vent (optional)

Tape measure

Marker

Tin snips

Chalk line

Wood saw

Clamps

Drill

Scissors

Staple gun

Caulk gun

Paintbrush

Chisel

Hammer

Masonry drill bit (long as possible)

Gorilla Glue

Electrical tape

Wire strippers

There are a few variations on this design, depending on the materials you have available and the type of room you will be heating.

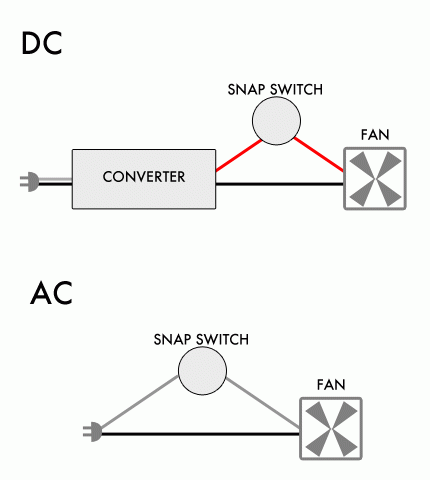

For the fan, you need to find a small, quiet unit that is capable of delivering at least 100 CFM. If you can find one of these that uses 110 VAC, then you don’t need anything else. Most small fans of this type are 12 VDC, which means that you need a converter from 110 VAC to 12 VDC. These converters are readily available from junk or surplus electronics, and are commonly referred to as “wall warts.” The converter should output at least 12 volts DC, and double the amps your fan is rated for. This gives enough room for the fan’s startup surge.

The first problem you may encounter is the size of your transparent, corrugated plastic. If you can find a 4 feet sheet, so much the better, as that will match the size that the insulation comes in. However, if you can only find a 3 feet wide piece, don’t worry. You can still use this design, but you will have to cut your insulation down to fit it, and then adjust the metal channel walls, so that they too match the new size.

The next issue is the inside height of your room. You will have two holes through your south facing wall, one at the top and one at the bottom. Air will be drawn from the bottom hole into the bottom of the heating unit outside. This is because it will take less energy to heat the air from inside the house than from outside, as it will already be warmer than the external temperature. The air that has been heated by the unit will then blow down into the room from the top hole. The problem with this is that, in order to make the most out of your heater, you will want the distance between the outside edges of the two holes to be about 8 feet (a little less is OK).

If your room is eight feet tall, construction of the unit will be easier, cheaper and more efficient. Easier, because you will be able to cut a hole through the bottom and top of the heater’s backing (insulation), instead of having to go out through the sides of the heater’s wall, which is more complicated. Cheaper, because you will need less 4” dryer vent, as it will be going straight through the house’s wall, instead of having to curve to the side before going inside. More efficient, because the temperature inside the unit will match the air coming into the room, whereas if you have to go to the side, you will lose a little heat through the extra dryer vent. You can compensate for this by painting the exposed vent black, or, even better, wrap it with insulation.

During the course of this article, we will be mostly describing how to attach this unit to a smaller room. For a start, it is probably more common to have rooms that are less than eight feet tall. Secondly, it is more complicated, and therefore requires a little more explanation. However, wherever the instructions differ for a tall room, we will add notes in bold.

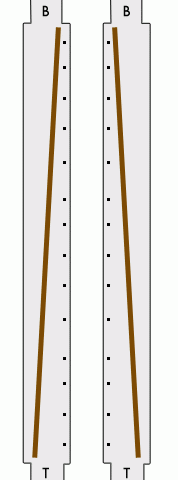

You want to clamp these pieces of molding to the 4” part of the pieces of channel, but at a diagonal. The ends near the B tabs want to be ½” in from the inside edge, so that when the two channels are side by side, the molding from one channel will be close to the other at the B end. The insulation (which is ½” thick) will eventually slot into this ½” space.

You want to clamp these pieces of molding to the 4” part of the pieces of channel, but at a diagonal. The ends near the B tabs want to be ½” in from the inside edge, so that when the two channels are side by side, the molding from one channel will be close to the other at the B end. The insulation (which is ½” thick) will eventually slot into this ½” space.[If you have an 8 ft. tall room, as described in Step 1:Considerations, you will need to do the following steps at this stage:

This step is largely dependent on the type of walls you have and how thick they are. The principals are the same, but solid concrete walls, for example, will be a lot harder than adobe, and will take you longer. If you have loose fill inside your walls, you will have to be prepared to support the fill as you chip out the wall, as they do in mines, so that the fill doesn’t all fall into the room.

The unit will be almost upright, although the bottom wants to be held a couple of inches out from the wall and the top touching the wall. This slight angle means that the bottom wall braces will be slightly less than right angles.

The heater is not that heavy, so the weight to be supported is not much. The braces are more to protect it from wind damage.

[For the 8 ft. tall room model, your dryer vents should already be through the wall. Gently stretch or pull the accordion to bring them flush with the wall on the bottom or flush with the beveled out part for the fan at the top. If you find that you have to push hard, get someone to hold the vent on the outside of the wall, and push against them rather than against the insulation of the unit.]

If your fan is AC rated, then cut the extension cord, leaving enough wire to go to a wall outlet and then connect to the fan. Connect one wire of the extension to free wire of the snap switch, and the other wire to the fan. Skip to step 5.

If your fan is AC rated, then cut the extension cord, leaving enough wire to go to a wall outlet and then connect to the fan. Connect one wire of the extension to free wire of the snap switch, and the other wire to the fan. Skip to step 5.

So now you have a brand new solar heater installed. As long as there is sun, the fan will run and heat up your room. The air coming from the fan will be nice and warm, but it won’t get hot enough to burn or damage anything.

During the warmer months, you can unplug it and remove the top dryer vent from the manifold to prevent hot air entering the home. Alternatively, just cover the solar heater with a thick blanket to prevent any solar gain.