Water is perhaps the most important requirement for your property. And storage is the most costly part of any water system.

Plastic tanks are easy to set up, but they are very expensive in larger sizes. Concrete ones are durable, but ill advised for any beginner, as they are prone to leaks if not done correctly, especially where the walls and floor meet. We have found that the shell and liner system described in this article is by far the best option for us. It’s cheap, easy (even for just two people), and quick.

50 bricks (Compressed Earth or similar)

5 pieces 10ft x 4ft pieces of 18 gauge sheet metal

60 x 3/8″ X 2″ bolts, nuts and washers

50 ft of 2″ angle iron

50 ft of 2″ metal strip

12 x 3/4″ PVC Ts

9 pieces of 20 ft 3/4″ PVC

6 pieces of 20 ft 1/2″ rebar

18 ft x 18 ft vinyl tarp

18 ft x 18 ft mesh (hail screen)

2x 5 gallon buckets of acrylic

3 bags cement

1x 1 ½” bulkhead

1x 1 ½” nipple, 3″ long

1x 1 ½” valve

Silicon

Pond liner – potable if needed – 16 ft diameter, 5 ft tall

1x 3″ bulkhead

2x 3″ male thread to PVC adaptors

3x 3″ Elbows

1x 3″ T

1x 3″ cap

20ft X 3″ pipe

Dirt-working tools (shovel, pic, etc.)

String

Tamper or Compactor

Level

Marker

Measuring Tape

Drill

Circular Saw

Welder

1/8″ drill bit

3/8″ drill bit

Crescent wrenches

Hole saws

Saw (for PVC)

Concrete mixing tools

Large brushes with long handles

This article is based on a 16ft diameter, 4 ft tall tank, holding 6,000 gallons. However, you can alter the dimensions to fit your needs.

Round tank:

π (3.14) x radius x radius x height x 7.5 = gallons

(e.g. 3.14 x 8ft x 8ft x 4ft x 7.5 = 6028.8 gallons)

Square tank:

length x width x height x 7.5 = gallons

(e.g. a 18ft square that is 4ft tall will hold 9,720 gallons)

Liner Dimensions:

You want to make your liner a little larger than the tank’s dimensions, so that it has some slack. Also make it 1ft taller than your tank’s walls.

Even though a square tank is more efficient with space and thus your liner, we would unequivocally recommend going with a circular design. We have done both and the round one is far stronger and requires less work. Any money you might save on the liner for a square tank is negated by the extra strength you will have to add to the frame. If you decide to go square, bury the bottom 1/3 of the tank.

There are three sets of plumbing to consider: the intake (which can go into the tank roof and will be addressed in the roof section of these instructions), the outlet and the overflow.

Outlet: You can make this any size you wish. The larger it is, the faster water will come out, but the more expensive your pipes will be. Generally, pipes to a house are either 1/2″ or 3/4″. You want the outlet to be as low to the floor as you can get, and in a location that is convenient to wherever you want to use the water. On our tanks, we use 1 1/2″ outlet sizes, to be able to hook multiple tanks together.

Overflow: The size of the overflow depends on the source of water that will be filling the cistern. For a rain catchment system, your overflow wants to be able to match or exceed the size of pipes going from your gutters to the tank. At least 3″ is recommended, although more if the catchment area is very large and you experience heavy, fast rains. The overflow point will want to go as close to the top of the walls as you can make it. Think about where you want the overflow to go – whether to another cistern, an orchard, or somewhere else that can safely handle the excess water – and place it accordingly.

Please note, that in this system the overflow point and the overflow pipe are 2 different things. Because we have a self cleaning overflow design, the overflow point is actually higher than the pipe hole in the metal wall.

This roof is designed to allow any rain that falls on it to enter the tank.

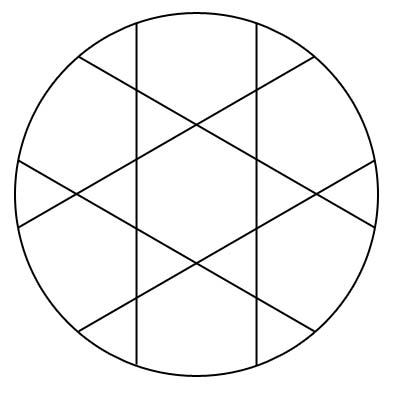

Feed the rebar into each piece of PVC and then place each piece of reinforced PVC into the Ts on the outer circle according to the diagram. As each piece goes into place, the structure will get increasingly strong.

Feed the rebar into each piece of PVC and then place each piece of reinforced PVC into the Ts on the outer circle according to the diagram. As each piece goes into place, the structure will get increasingly strong.(NOTE: If you are using the tank for fish, use greenhouse plastic instead of the tarp and mesh, and you are done).